Introduction to Through Hole PCB Assembly for Modern Electronics

Through Hole PCB Assembly remains a trusted method for building electronic circuits that demand exceptional durability and strong mechanical bonds. Despite the rise of surface mount technology, this assembly method continues to hold a vital place in industries that require components to withstand high stress, temperature variations, and harsh environmental conditions. By inserting component leads into pre-drilled holes on the board and soldering them securely, Through Hole PCB Assembly creates reliable connections that can handle demanding applications such as aerospace, automotive, and industrial machinery.

Why Through Hole PCB Assembly is a Preferred Choice for Reliability

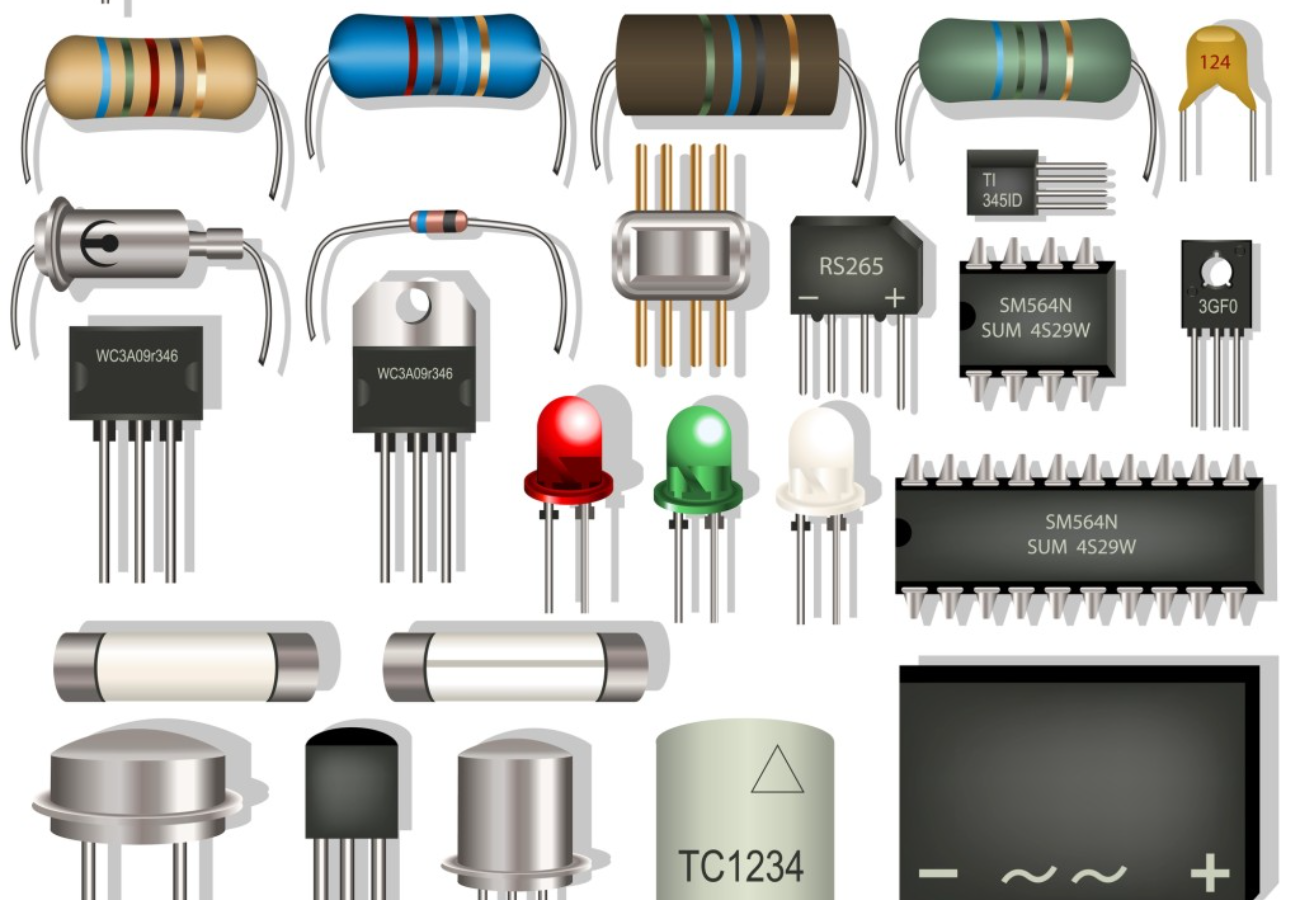

The strength of Through Hole PCB Assembly lies in its ability to provide a firm mechanical connection between components and the PCB. This is particularly beneficial for large components such as transformers, connectors, and heavy capacitors that need extra stability during operation. The process ensures that components remain secure even under constant vibration or mechanical stress, making it the go-to solution for products where failure is not an option. For this reason, many critical systems continue to rely on Through Hole PCB Assembly as the standard for durability and reliability.

The Process Behind Effective Through Hole PCB Assembly

Creating a high-quality board with Through Hole PCB Assembly involves several precise steps. First, holes are drilled into the PCB according to the design layout. The component leads are then placed through these holes and soldered either manually or using wave soldering machines. This soldering method not only establishes strong electrical connections but also ensures a robust mechanical bond. In applications where absolute precision is required, skilled technicians often handle parts of the process manually, guaranteeing accuracy and reducing the chance of defects.

Applications That Benefit from Through Hole PCB Assembly

Many industries continue to depend on Through Hole PCB Assembly for mission-critical electronics. Military and aerospace sectors value its ruggedness and ability to endure extreme temperatures and pressure. The automotive industry relies on it for components exposed to constant vibration and movement. In power electronics, where high current and heat are factors, Through Hole PCB Assembly offers a secure way to mount heavy-duty components. Even in consumer electronics, certain products still use this method for its proven stability and reliability over long operating lifespans.

Quality Control Measures in Through Hole PCB Assembly

Since the integrity of each connection is vital, Through Hole PCB Assembly involves rigorous inspection and testing. Visual inspections ensure that solder joints are clean, well-formed, and free from defects like cold joints or bridging. In more advanced facilities, automated optical inspection systems are used to detect issues at a microscopic level. Electrical testing follows to verify that the assembled board functions exactly as intended. These measures ensure that every Through Hole PCB Assembly meets high-quality standards and delivers consistent performance.

Advantages of Choosing Through Hole PCB Assembly for Your Projects

One of the key benefits of Through Hole PCB Assembly is its superior mechanical strength compared to other assembly methods. This makes it ideal for products expected to endure heavy handling, physical impact, or environmental challenges. Additionally, the method is highly adaptable, allowing for mixed-technology boards that combine through-hole and surface mount components for optimized performance. Through Hole PCB Assembly also offers easy component replacement and rework, making it a practical choice for repairable and upgradable systems.

The Future of Through Hole PCB Assembly in a Changing Industry

While modern electronics manufacturing is dominated by surface mount technology, Through Hole PCB Assembly will continue to play a critical role in specialized applications. Advancements in soldering technology, improved component designs, and hybrid assembly techniques ensure that this method remains relevant. As industries such as electric vehicles, renewable energy, and industrial automation expand, the demand for dependable Through Hole PCB Assembly is expected to grow, maintaining its position as a cornerstone of durable electronics production.

Final Thoughts on Through Hole PCB Assembly

Through Hole PCB Assembly is more than just an older manufacturing method—it is a proven solution for creating long-lasting, high-performance electronic products. Its unmatched mechanical strength, adaptability, and reliability make it indispensable for a wide range of industries. Whether for aerospace systems, automotive applications, or high-power industrial equipment, Through Hole PCB Assembly continues to deliver dependable results, ensuring that critical electronics function flawlessly in the most challenging conditions.